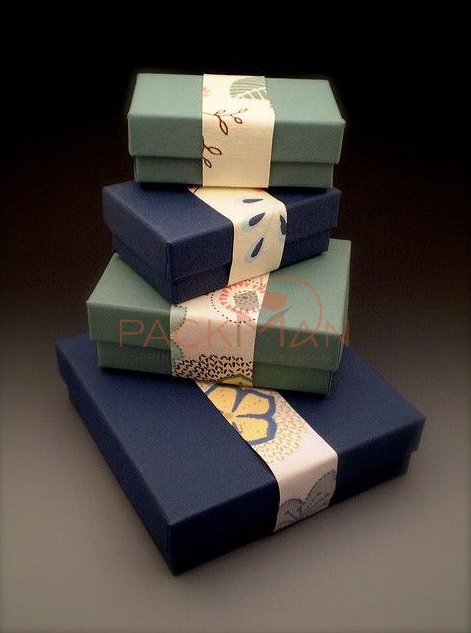

Packaging with some sleeves is a great way for you to get the most out of your packaging experience. You may already know what sleeves are, but here’s a recap for those who don’t know. Sleeves are cardboard strips that wrap around products, and it can save you money on boxes.

Sleeves can be further customized by adding some branding, information on products, and promo offers. There is also a special finish that further adds to the unique touch of things.

The benefits of Sleeves

Sleeves that are colored offer a variety of different benefits that can be used. First they’re professional, and cost very little. sleeves are simple, and they cost far less than building a whole case.

They’re also further adaptable to every single industry and sector, and it’s used within all sectors of marketing.

They’re sustainable as well and offer special benefits for special offers that are there. When you adapt this to promotional launches, reviewing it across different seasons can also be pretty expensive over time. Sleeves are versatile, and they cost far less than a regular box.

They also offer an environmental footprint. Cardboard is pretty environmentally friendly, but sleeves save you a lot more on the raw materials and the ink, so it’s even less than before.

Let’s take the case of a n artisan pasta, where the sleeve showcases a product emphasis, and the strength of a brand through some graphics that are color illustrated, offering a newfound brilliance not seen before from this type of product.

On the topic of food, let’s also talk about meat sleeves that are used. You can get them for cuts, and then you can use a shrink wrap to seal this, and the sleeve will occupy just a part of this package. This offers a balance by creating a premium package with the smallest amount of packaging that’s possible.

Another great element that packaging sleeves offer is the tools. Let’s say you’re selling a cutting board. For the most part, those are a bit bland and boring, but with a sleeve, you show off the packaging, creating a message, which is mostly the fact that it’s handmade, and a very unique crafting piece that’s possible.

Cosmetics are even using this. Nowadays, you can get cosmetic kits for ideal skin routines, and other such things. While it might look at first like a purse or a case, with the sleeve added, it creates the perfect item, with the least amount of expenses, and the largest impact that can be there.

Then of course, there is the clothing sector that benefits from sleeves. Socks and stockings are but one example. Think about it, you get different hosiery, and it has on the sleeve, the brand, the composition of such, and finally that size. This is something that’s super simple for a lot of people to use. It’s also ideal for the customization aspects of this. it’s good if you’re looking to add some personalized touches to your products as needed.

In conclusion, the best way to market a lot of your products is the sleeve. Don’t underestimate this, as it’s one of the best, most effective, and also flexible sorts of packaging solutions. You can get prototypes for the packaging to see if that’s the best way for you to do this. You can also get some packing and other shipping and printing aspects covered with this too. For a lot of people, this level of marketing and choosing of your products offers the best means possible to create an ideal product for your needs too.